McMaster-Carr (link) is a great resource for not only components and materials but also for information that can aid you in design. It can be used in a number of ways.

The most simple way is that you can use it to determine the rough cost of the part. You can see if your component fits within a standard size of material that they offer and then compare costs between material types. They also offer information on the machinability of materials which is important on our end as it will determine costs.

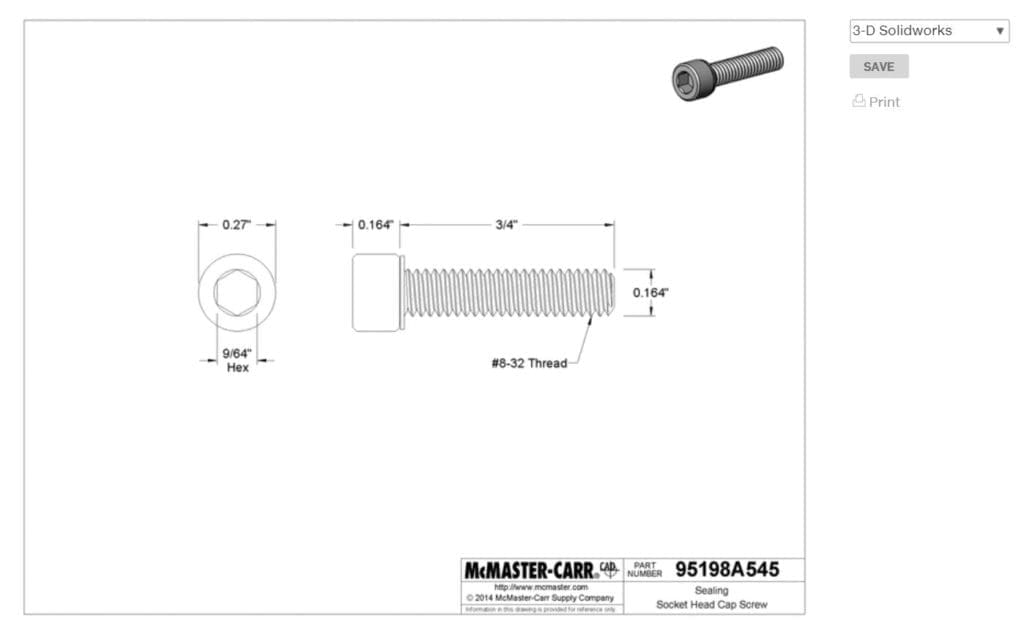

The other slightly more interesting way to use them is to leverage all the component models that they have on their website. You can design an assembly, place component models that McMaster offers for free in it and then call them out in your BOM and drawings. These models can also be chopped up to be used in your own designs. Why model threads when you can just chop them of a freely available model from them.

The third most interesting way (to us at least) is to determine validity of your design by looking at the tooling section on the McMaster site. A lot of times we see drawings with features that are easy to design but expensive to realize. Deep pockets with small corner radii, oddly sized holes, strange corner fillet diameters are all features that will add to the price of the piece. Most of the time they are all doable, but with a little research and small modifications they can all be made cheaper. For pocket features you can take a look at endmills and see the ratio of length of cut versus endmill radius. For holes you can look at available drills and see if they come in the sizes and lengths that your drawing is calling for. For corner radii you can see if the corner radii mills are actually available. A .25 corner radius cutter is a lot easier to find than a .24. Of course we are not saying that just because the site does not offer a specific tool that you should change your design it just makes some things easier.

All images downloaded from McMaster-Carr