We feel that this deserves a separate section as often we see models and drawings that have features with sharp inner corners, and we think that we can provide some helpful hints.

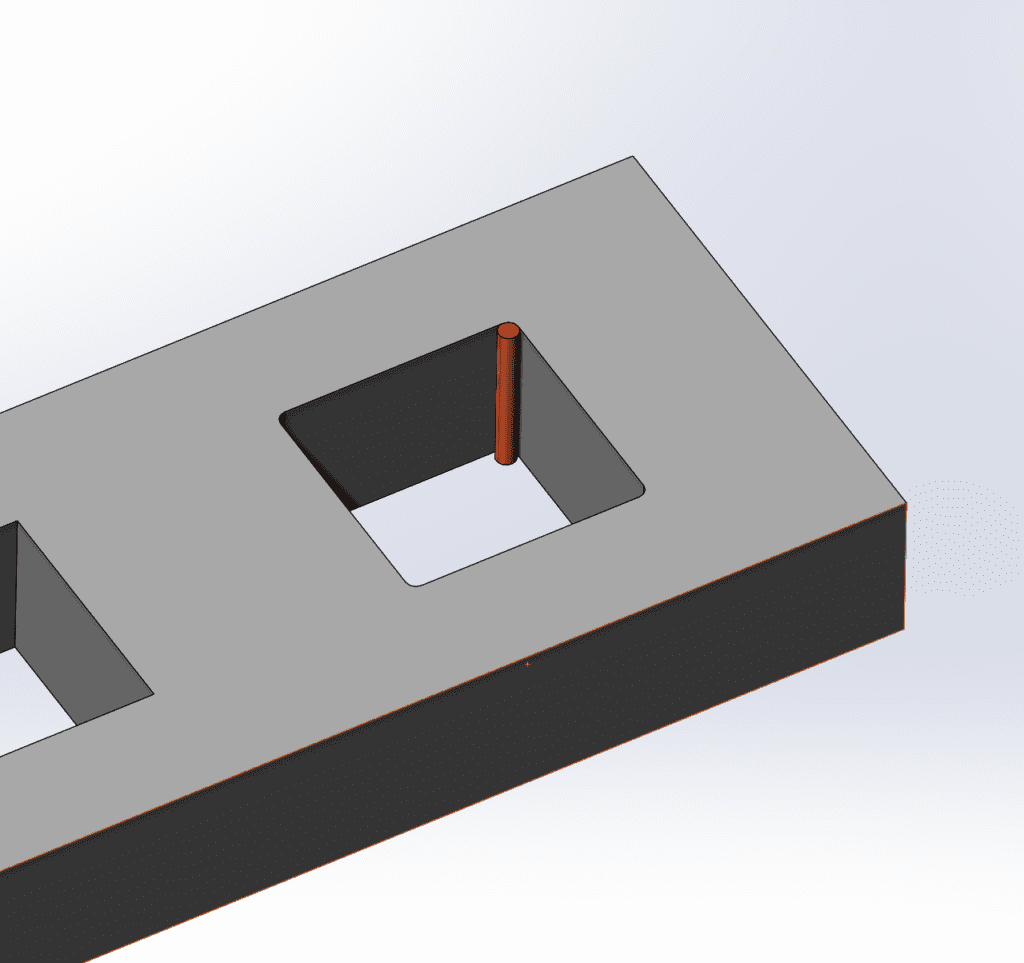

The mill primarily removes metal using a round tool, as such it will cut an inner corner of a feature by leaving a filet with a radius equivalent to half the diameter of the tool.

This can be mitigated by using a smaller diameter tool but there are a number of issues associated with this. 1. There will always be a radius 2. Each time the diameter of the tool is made smaller the strength of the tool has to be reduced as well. This will slow down the cutting as more steps downwards might have to be taken, it will probably reduce the rate of feed for the tool, and at a certain point will make it almost impossible as a necessary tool might not be available or physically possible.

A more correct way to counteract this problem is to either design parts with a fillet in the inner corners or to provide relief for a tool to use. In both cases the deeper the pocket the bigger the fillet or relief will have to be.

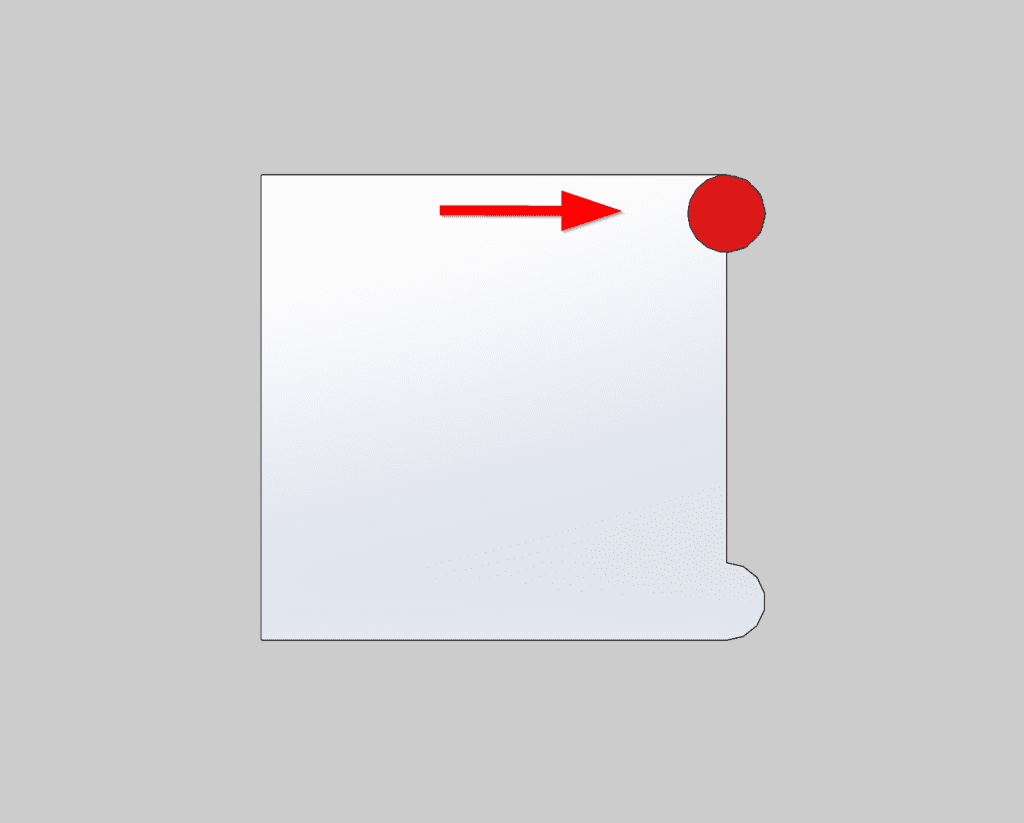

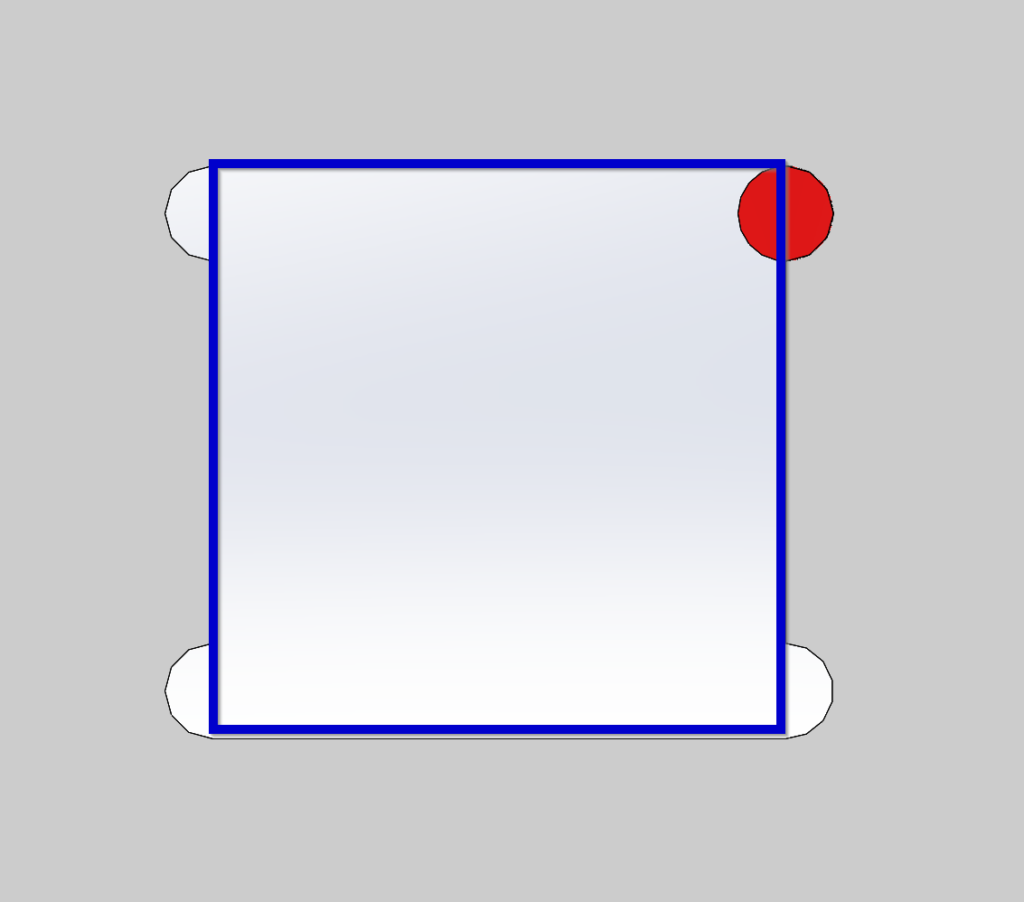

When we talk about relief we mean something that can be described as “Mickey Mouse ears” Please take a look at the picture below.

If providing relief and or resorting to the fillet it is also prudent to make them slightly more over sized than the tool used to cut them. In imperial, as most tools are a in fractions of an inch (1/8, 1/4 so on) one should add something to those standard sizes ie the redius should be something like .13 .27 .6. The same for metric. This is done so that the tool is not forced to cut the whole arc at the same time but rather part just part of it, especially when cutting a finishing pass.

The other way to achieve square inner corners is to split the part or provide a way for the machinist to cut them in a different orientation.